Indicator additives for a safe hydrogen economy

Green hydrogen produced from renewable energy sources will be a key component of a sustainable and climate-friendly energy economy in the future. In particular, the safety aspect is a major challenge for the realization of a hydrogen economy. Hydrogen gas, which will be used almost everywhere as a flexible energy carrier, cannot be perceived by the human senses. However, it is highly flammable and explosive in air, as historical events (the fire on the zeppelin "Hindenburg" in 1937) have shown.

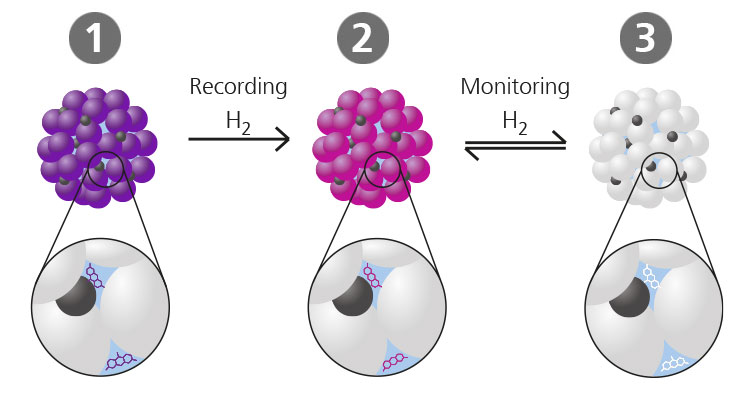

In order to increase safety within the complex hydrogen infrastructure, researchers at the Friedrich-Alexander University of Erlangen-Nuremberg (FAU) and the Fraunhofer Institute for Silicate Research ISC in Wuerzburg have investigated the basic functional mechanisms for a new type of hydrogen sensor.