Carrier particles for various applications such as catalysts or sensor dyes

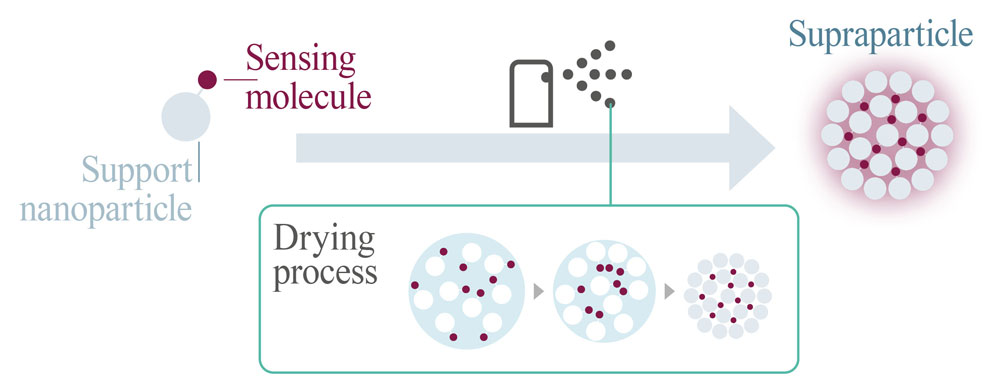

Supraparticles, micrometer-sized particle structures consisting of various nanomaterials, can be used in a wide variety of applications (catalysis, sensor technology, recycling, etc.).

The size, morphology and properties of the supraparticles can be influenced by the building blocks. The use of primary particles of different sizes makes it possible to adjust the particle surface and the pore size distribution of the supraparticles in a targeted manner in order to adapt them to the desired requirements. The supraparticulate structure allows the unique properties that materials exhibit on the nanoscale to be transferred to the microscale and, at the same time, new properties to be generated through the forced assembly of different nanoparticles in a defined space.

In the Particle Technology group at the Fraunhofer ISC, we are working on gaining a better understanding of the manufacturing processes of supraparticles and thus developing targeted systems that can be customized for a wide range of applications. A large number of different systems can be realized in a modular way using a wide variety of primary components.