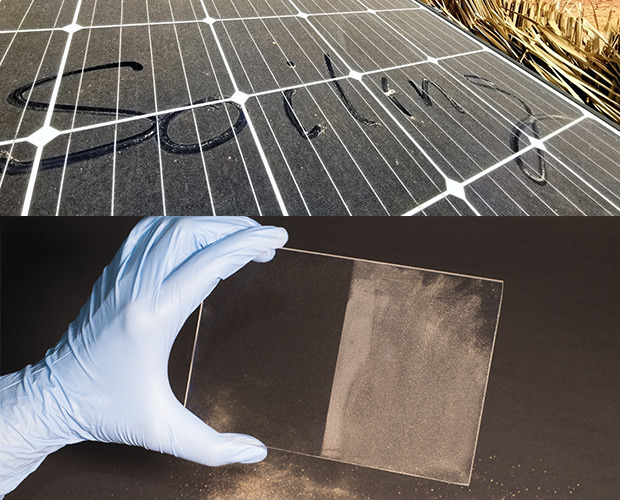

In its “Nanoparticle Kitchen”, the Fraunhofer ISC develops customized particles for a wide range of applications

These particles are used, among other things, to produce coatings that prove their functionality in layer stacks of a component or product. In addition to the material-specific properties of the particle-based coatings, the size of the particles influences the microstructure of the coatings produced and therefore their functionality.

Customized particle-based coatings

Are you looking for particle-based coatings with special functionalities?